Pump failure

It is difficult to say the exact reason of pump failure. The most common reason of pump failure can be the leakages. There are some possible reasons of all pumps/water pump failure causes is listed below:-Pump failure causesIncorrect pump installation: Incorrect pump installation are the reason of pump failure. Pumps should be installed or mounted as per the guidance of manufacturer.

Blockage: Blockage is another reason of pump failure. Some difficult substances that change the viscosity of liquids resulting pump getting jam or damage

Power Issue: Power tripping and power spikes is another reason of pump failure. Poor power connection or wiring that damage the normal operation of pump that’s why it can burn or getting failure.

Basic hydraulic pneumatic system components Types of hydraulic pump Hydraulic cylinder speed calculator Hydraulic directional control valve types Basic pneumatic system

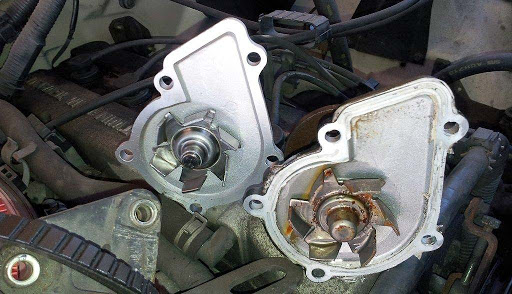

Water pump failure causes

Usually water pump is used in engine cooling system. Water pumps are driven externally with pulley and belt.

There are many reasons of water pump failure. It can be poor wiring connection, water contamination, improper sealing, installation error, overloads and power tripping or power spikes. The faulty mechanical seal installation is the main cause of water pump failure.

Common failure factors

Dry running: If the pumps runs without the fluid that is known as dry running. When the pump starts dry running then the seal and impellers became overheats that is the reason of pump failure.Improper installation of seals: The improper installation of seals that is the cause of coolant leakage resulting the pump damage or fail.

Incompatible coolant: incompatible coolant that does not offers manufacturer and it contains contaminants which damages the cavity and seals that leads to the water pump failure.

Improper installation of belts: Installed the belt misaligned, inaccurate belt tension and over tightening can be the reason of water pump failure.

Without except these problems there are several reasons which can fail your pumps including the pump cavitation, suction problem and higher vibration etc.

Fuel pump failure causes

A fuel pump supplies the fuel from gas tank to engine. The fuel pump mounted inside the fuel tank. If the fuel supply is stopped the vehicle engine can’t start that's why it is important to continue fuel supply to the engine.

There are some common reasons of fuel pump failure

Power issues: Electricity or power is another issue of pump failure. Poor electrical connections, rusted connectors, loose connections and voltage drops can be the issues of pump failures.Contamination of Fuel: Contaminant fuel contains rust debris and dirt that resist the filter strainer from getting sucked the fuel properly finally its leading to fuel pump failure.

Low Fuel level: The low fuel level is another reason of fuel pump failure. When fuel falls below a certain level thus it destroys the cooling of fuel pump and Solenoid coils get damaged resulting the cause of pump failure.

Hydraulic pump failure causes

It is difficult to specify the exact reason of hydraulic pump failure case their construction is different in each manufacturer but certain failures are common for every of pumps. There are four cause of hydraulic pump failure is described below:

Fluid contamination: Contaminant is one of the most common reasons of hydraulic pump failure. Fluid contaminant might say metal particles and chemical particles. When the contaminant particles size is bigger than the surface clearance, creates friction and get the pump damage.

Air in the pump: Low fluid levels creates aeration of the pump that means air is entered to the pump when the fluid level is low and pumps makes noisy sound and start overheating. During the fluid return to the tank like foamy and full of bubbles thus creates aeration.

Cavitation: When the pumps suffer from cavitation it generates particles. Cavitation is seen around the pump internal surface as it is the removal issue of small particles from the surface. Hydraulic pump is vaporized due to cavitation thus pumps creates bubbles in the oil and carried to discharge port. Bubbles in the oil and cavitation oils are both done the pump failures.

Excessive heat: Excessive heat that damage the seals and O-rings and also damage the viscosity of fluids.

Improper fluid viscosity: High viscous fluid can’t flow easily to the pump and it is more difficult to deliver the fluids for the pump thus the pump gets damaged or failure.

Excessive pressure: Overloads or continue excessive pressure that leads to damage the hydraulic pump.

To avoid hydraulic system or pump failure it is needed to use Clean oil and High-quality hydraulic filter. Filter should clean depending on the lubrication oil condition. And need to use cooling system to maintain the safe temperature for the hydraulic system.

Our facebook group

Post a Comment