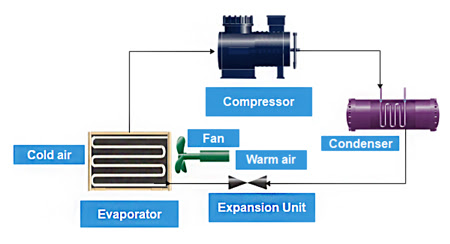

Chillers have following four major components:

Evaporator

Evaporator takes heat from the room air and that heat cause the liquid refrigerant to evaporate.Compressor

Compressor increase the temperature and pressure of the refrigerant gas.Condenser

Condenser use external coolant either air or cool water to exchange heat from the refrigerant.Expansion component

The expansion unit reduces the temperature and pressure of the liquid refrigerant to be sent to evaporator.Working of chillers start with phase change process of the liquid coolant to gas in the evaporator where heat from hot air is taken by the low temperature coolant. The heated gaseous refrigerant moves to the compressor where its temperature and pressure increases. The high-pressure gaseous refrigerant loses heat in the heat exchanger and changes to liquid state. The liquid refrigerant passes through expansion valve and enters the evaporator ideally low pressure and low temperature liquid. This completes the working cycle of the chiller.

There are two main types of chiller

- Vapor Compression Chillers

- Vapor Absorption Chillers

Vapor Compression Chillers

In vapor compression chillers, compressor is used to increase the pressure and temperature of the refrigerant so that heat can be dissipated in the condenser. The working principal of the vapor compression chillers is described above.There are further two types of vapor compression chillers:

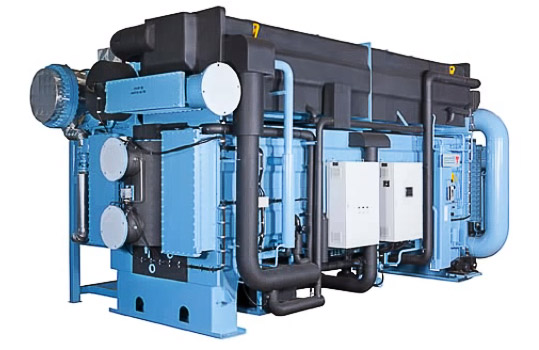

Water-Cooled Chillers

types of chille

In water cooled chillers, heat is removed from the refrigerant by the water. External pumps are used to pump the cooled water from the cooling tower to the condenser where water cools the refrigerant. High heat capacity of water than air enables it to exchange more heat than air. So, it is efficient than air cooled chillers. They produce less noise and can be used for small- and large-scale applications.Air Cooled Chillers types of chiller

In air cooled chillers, heat is removed from the refrigerant by

the air. External fan pushes the air through the condenser coils to cool the

refrigerant. These chillers are used where the additional heat produced is not a

problem. This additional heated air can be used to keep the warm temperature in

the area during winters. The maintenance requirements are low for air cooled

chillers and use less electrical energy.

Based on type of compressor used we can divide Vapor Compression Chillers into four types:

- Reciprocating compressor chillers

- Centrifugal compressor chillers

- Screw compressor chillers

- Scroll compressor chiller

Post a Comment