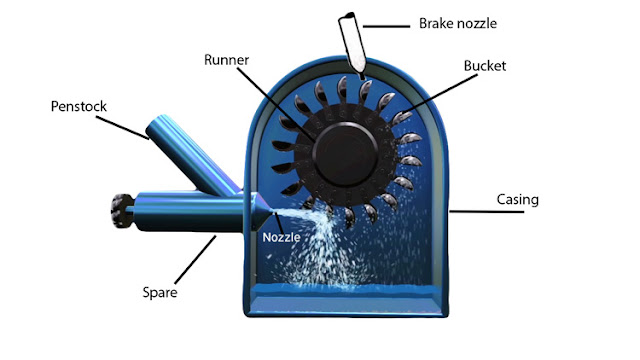

Pelton Turbine

Impulse turbine is such a type of turbine that rotates the turbine wheel when the total pressure of the water to the turbine turns into a kinetic force on the nozzle and jet.it is installed horizontally or vertically. Vertically installed turbine has several of nozzles can be employed that resulting turbine gets high speeds of rotations.The Pelton turbine is essentially a type of Impulse turbine. In 1847, Lester Allan Pelton invented this type of turbine, so according to his name, it is called Pelton Turbine.

How does Pelton turbine works

When the level of water stored in the dam is increased to a certain height, water starts flowing from the dam through the penstock. With the nozzle at the end of the penstock, the water flows into the turbine at a rapid rate and then the runner begins to rotate. The other end of this runner is again connected to the generator shaft, so that when the runner is rotating, the generator shaft rotates.In a jet powered Pelton turbine, the water flow level is controlled by a single spear rod. Again, the water flow is controlled by the spear bar, according to the number of jets driven by two or more jets.

Typically, the effective height of the water in the Pelton turbine is from 1 meter to 5 meters. The relative speed is from 2.5 to 5.

The Pelton turbine consists of the following parts

-

- Penstock

- Spear

- Nozzle

- Buckets

- Runner

- Brake Nozzle

Spear: It looks like a spear bar and its main function is to control the water entering the turbine.

Nozzle: It is connected to the end of the penstock, its main function is to increase the speed of the water and run the buckets of the turbine.

Buckets: Each Pelton turbine runner has a fixed number of buckets attached. The buckets begin to rotate along the runner with the water hit.

Runner: Runner is a heavy circular disc on which the buckets are attached.

Brake Nozzle: When the turbine needs to be closed, the buckets are rotated in the opposite direction by pouring water from the brake nozzle on the bucket.

Casing: The structure that the entire setup of the turbine is enclosed in is called turbine casing.

Advantages

- It is more efficient than other turbines.

- Its overall efficiency is much higher.

- Assembly is easy to do.

- This turbine can be operated at low discharge.

- Its efficiency curve is flat.

- It can work by silted water.

Disadvantages

- its efficiency decreases due to long time operation.

- Its components are large in size.

- The variation of its operating head is very difficult to control.

- When the level of tail water is relatively large compared to the total head, its operating head cannot be used.

Hey there, I think your website might be having browser compatibility issues. When I look at your blog site in Chrome, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, wonderful blog!

ReplyDeleteIt is updated

DeletePost a Comment