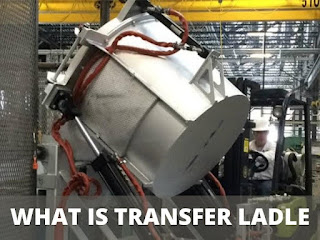

CHNZBTECH – BEST TRANSFER LADLE MANUFACTURER IN CHINA

A transfer ladle is a container used to carry and pour molten metal, from the furnace to the pouring unit. If you are planning to buy a transfer ladle for your company according to your needs, then you are at the right place. Today, we will tell you about the different types and functions of transfer ladles available in the market and the best ladle manufacturer in China – CHNZBTECH.

WHERE

TRANSFER LADLE IS USED?

Transfer

ladle is often used in foundries, and if it is small, it can be carried by hand

in a container with a handle that resembles a kitchen ladle, and if it is

large, it can carry up to 300 tons of molten metal in a steel mill. Many

non-ferrous foundries use ceramic crucibles for transporting and pouring molten

metal, which is also sometimes called ladle.

TYPES

OF TRANSFER LADLES

Transfer

ladles can be roughly classified into the following three types.

·

Casting ladle

A

casting ladle is a transfer ladle used to pour molten metal into a mold to make

a casting.

·

Transport ladle

A transport ladle is a transfer ladle used to convey large amounts of molten metal from one process to another. Typically, a transfer ladle is used to convey the melt from the primary melting furnace to the holding furnace or automatic pouring unit.

·

Processing ladle

A

processing ladle is a ladle used in processes that are carried out in the ladle

to change some of the properties of the molten metal. A typical example is the

conversion of cast iron into ductile iron by adding various elements to the

transfer ladle.

FUNCTIONS

OF TRANSFER LADLE

Various

modifications may be made to the basic design of these ladles to improve the

ladle's utility for that particular practice. In addition, the common necessary

functions are:

·

Possesses heat

insulation properties so that heat is not released or radiated from molten metal.

·

Thermal insulation

to prevent the surroundings from becoming hot and to maintain the safety of the

surroundings.

·

Strong enough to

hold the heavy molten metal.

·

Wear resistance and

spalling resistance against molten metal.

·

Heat resistance and strength

of refractories such as blast furnaces.

· Ease of handling during pouring.

LINING OF TRANSFER LADLES (

Ladles

are lined with a refractory lining unless they are used with alloys with very

low melting points. It is to prevent the steel container from being damaged

when transporting high-melting-point metals using a ladle.

There

are many different materials for refractory linings, and the correct choice is

highly dependent on each foundry's practices. Traditionally, ladles were lined

with refractory bricks before casting, but refractory concrete is replacing

this in many countries.

Foundry

ladles are usually valued more for their working capacity than for their

physical size. A hand-held ladle has a long handle to keep the heat of the metal

away from the person holding it. Its capacity is limited to what a person can

safely handle.

Large

ladles are commonly called geared crane ladles. Its capacity is generally

determined by the function of the ladle. A small hand-held ladle may be a crucible

fitted with a carrier. However, the casting ladle found in most foundries is

equipped with a hoisting device so that the container can be transported by

overhead crane, monorail, etc., and is usually made of steel with a mechanism

that rotates the container with a gearbox. The gearbox can be manually operated

or power controlled.

HOW

TRANSFER LADLES ARE DRIVEN?

Ladles

are sometimes driven on wheels or on special ladle transfer cars, such as in

steel mills, to transport very large quantities of molten metal. Others are

transported suspended from overhead cranes and tilted using a separate hoisting

device on the ceiling.

POURING

DESIGN OF TRANSFER LADLE

There

are two types of pouring design of ladle: "lip pour tilting type" and

"bottom pour bottom pouring type".

· In the lip pour method, the molten metal is poured

out by tilting the ladle, like pouring water from a jug.

· The bottom pour type has a pour spout at the bottom of the ladle and a stopper rod inserted. For pouring metal, the stopper is vertical, allowing the metal to pour out the bottom of the ladle. To stop pouring, insert the stopper rod back into the drain port.

Large

ladles, such as those used in the steel industry, use a slide mouth below the

tap hole.

Some

ladles are open at the top, while others have a cover. Small ones are often

open. However, for efficiency considerations, a lid seems necessary.

Those

with covers (some of which can be removed) have dome-shaped lids to retain the

radiant heat, allowing the heat to escape more slowly than the open-top

types.

Small ladles often do not have a cover, but ceramic fiber cloth or the like can be substituted.

FROM WHERE YOU CAN BUY TRANSFER LADLES?

You

can buy transfer ladle and other steel-making and ferroalloy equipment from

CHNZBTECH CO., LTD which is china’s largest ladle manufacturing company.

CHNZBTECH

is located in XI ‘AN, China. Its products are not only sold in China but are

also exported to other countries like Vietnam, Iran, and Southeast Asia.

CHNZBTECH covers installation, design, manufacturing, and commissions special

for steel-making equipment, integrated revamping, and upgrading of existing

plants of steel-making companies.

The

customer base of CHNZBTECH

Customers

of CHNZBTECH vary from large steel plants to famous design institutes, such as

JSPC of Japan, CERI, CISDI, WISDRI, and MGDRI. The company has also provided

complete steelmaking equipment to many enterprises such as Hyundai steel

company (300 tons LF), Iran Natanz steel company, and Vietnam TNC steel

company.

CHNZBTECH is also a qualified supplier of many enterprises like An Steel, Zenith, Shandong Shiheng, Tangshan Donghua, Tangshan Huafeng, and other iron and steel enterprises.

Benefits of buying from CHNZBTECH

By

providing complete sets of equipment and spare parts to many companies,

CHNZBTECH has won customers with excellent technical services.

Buying

transfer ladle and other steel-making equipment from CHNZBTECH will bring you

the following benefits;

·

State of the art design

·

High operational availability

·

Maintenance friendly

·

Efficient and economical equipment

How

you can contact CHNZBTECH

The

contact details of CHNZBTECH are as follows:

Address: Block A, Haibo square, 9th Fengcheng road,

Xi’an, China

Email:

leonard.kazo@chnzbtech.com

Phone:

+86-15596648075

Fax: 029-89613639

Website: www.chnzbtech.com

Post a Comment