Non return valve or check valve?

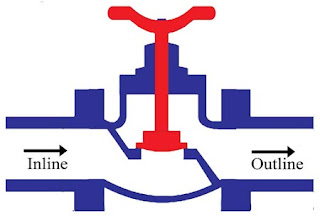

Non return valve or check valve is a one-way valve that allow one-way flow and prevent the reverse direction flow. Non return valve is also known as check valve.Types of check valveWhy used non return valve?

- Non return or checked valves protects the hydraulic system components against high pressure.

- Checking pressure surges attached with hydraulic forces.

- Instant stopping the reverse flow.

Different types of checke valve are listed below

- Lift check valve

- Swing check valve

- Disc check valve

- Wafer check valve

- Ball check valve

- Stop check valve

- Tilting disc check valve

- Vertical or inline check valve

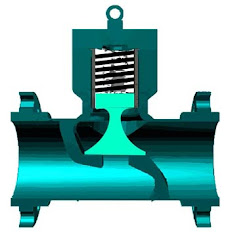

Lift check valve

Typically, Lift check valve is made for high pressure areas where speed of flow is very high. This check valve inlet and outlet port is divided with moving piston disc. When the flow goes forward direction the piston disc lift up and allow flow to go and when flow go reverse direction the piston disc closed automatically by fluid pressure.Swing check valves

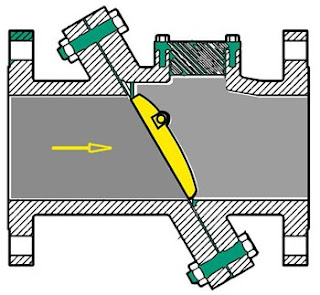

Swing check valve consist of a hang down disc which outer diameter is same as pipe boring. When flow starts going forward direction then fluid pressure lift the disc upward and allow the flow into the valve. For the reverse flow moves the disc to shut against the seat and stop the flow to downstream. When fluids are not passes through the pipe the disc stay closure with the valve.

Disc check valvesTypes of check valve

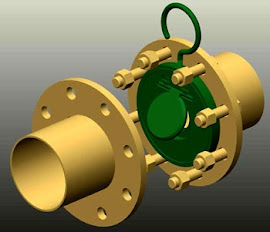

Wafer check valves

Wafer check valves installed between flanges and it takes low installation space. Its characteristics is same as the swing wafer check valve and most commonly where low pressure is required. To open the disc is require low pressure of flow and same is for closing while reverse flow starts. Usually, Wafer check valve use single door for opening and closing the flow and some other uses double doors.

Ball check valves

Ball check valves consist of rubber ball that seat on inlet to the valve. When flow go towards the forward direction it forces the ball and moves from the seat along with the guide rail and helps fluid to pass through the valve. When pressure does not act to the ball it slides back to the seat and stop reverse flow into the valve.

Stop check valve

Stop check vale are the most commonly used in boiler system and power plants. They are used to regulate, stop and start the flow and also work against to stop the back flow. If the screw totally down it holds the disc to the seat, which stops the flow through the valve.Tilting disc check valve

Tilting disc check valve characteristic’s is same as swing type check valve. It stay normally closed position while no flow passes through the valve. When flow starts going forward direction then the disc lifts up along with the pivot pin and allows flow to passes through the valve. If flow moves slower, the disc lift down depending on the velocity of flow. Reverse flow keeps the disc in a seat in the valve so flow does not go reverse direction.Vertical or Inline check valves

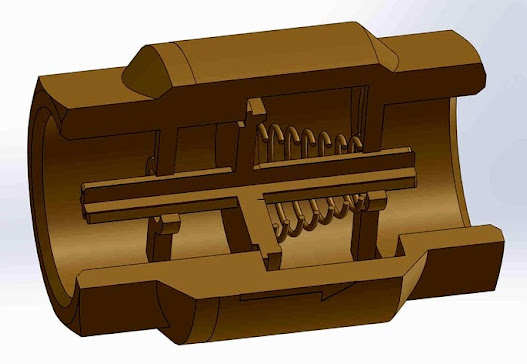

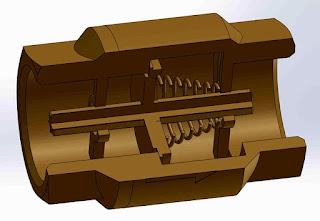

Vertical or inline check valve is used in both vertical and horizontal line. Inline check valve consists of disc, compression spring and seat. When fluids enter, disc moves from the seat and flow go through the valve and for the reverse flow disc slide back and seat on the valve and stop the flow.Types of check valve

Our facebook group

Basic hydraulic system components. Basic pneumatic system. Basic hydraulic components pneumatic system

Basic hydraulic system components. Basic pneumatic system. Basic hydraulic components pneumatic system

Post a Comment