Hydraulic Cylinder

Hydraulic cylinder is a linear actuator which extend forward and retract backward to transfer power by pressurized hydraulic fluid. Hydraulic cylinder is widely used in every hydraulic system in industrial or automobile applications. Basic hydraulic system pneumatic system components Types of hydraulic pump types Basic pneumatic system Hydraulic directional control valve

Hydraulic cylinder are consist of two main elements is barrel and piston

attached piston rod. There are also other elements like Rod end port, cap end

port, piston seal, tie rod, O-ring, Rod seal etc. Basic hydraulic system components of pneumatic system directional control valve

types of pump

Components of hydraulic cylinder

Barrel: Barrel is a seamless forged tube that is developed with high

quality surface inside.

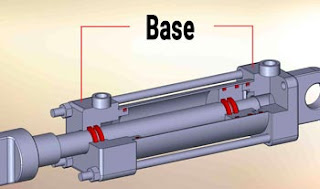

Base: Base is like a flange that

is connected with barrel and screwed with it.

cylinder speed calculator

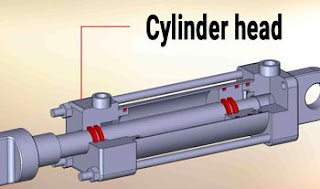

Cylinder head: Cylinder head is a part that contain wiper seal, wiper seal and rod end port.

Piston: Piston that separates the cylinder in two chambers. Piston has some piston seal, guide rings in outer surface that prevent passing oil between two chambers.

Piston rod: Usually piston rod mad with hard chrome-Plated cold-rolled steel. It is mounted with the piston and directly handle the load.

Port (Rod end port & Cap end port):

Fluid flow enter into the cylinder and and go out from the cylinder.

Types of hydraulic cylinder

Single acting hydraulic cylinder: In a Single acting cylinder, fluid pressure acts only the single side of the piston and on the other side of the piston move backward by mechanical load, spring and compressed air. When fluid enters and act to the piston end to developed pressure then it creates linear motion and extend the cylinder. If control valve releases the pressure then the cylinder moves backward this is how single acting cylinders works. Single acting cylinder is most commonly used in hydraulic ram, reciprocating engines etc.

Double acting hydraulic cylinder: In a double acting cylinder fluid acts in both side of the piston and can create linear motion in two directions. During the directional control valve coil energized (Coil A) the fluid enters to the inlet port that acting to the blind end of the piston and moves forward while the fluid out to the tank through rod end port (Cylinder extend). If the directional control valve energized again (Coil B) the flow of fluid changes the direction and fluid enters to the rod end port and out to the blind end port thus piston move backward (Cylinder retract).

Hydraulic cylinder calculation

Cylinder calculation is the most important things before selecting it for the hydraulic system.Cylinder stroke: The distance between piston rod fully extend and fully retract length is the stroke of the cylinder.

Hydraulic cylinder speed calculation:

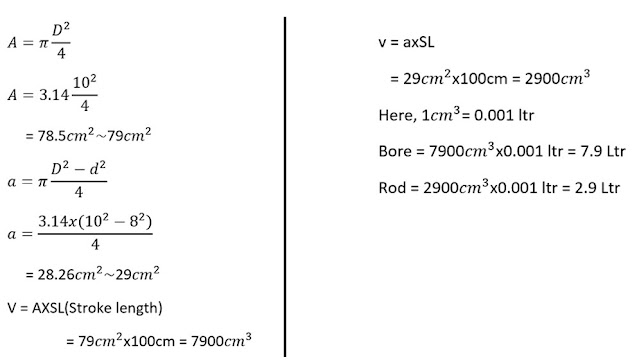

Hydraulic cylinder mathematical calculation:

A cylinder Bore is 100 mm stroke is 1000 mm rod diameter is 80 mm and hydraulic pump flow is 5 Lpm. Now calculate cylinder forward speed and retract speed? 5 Litter oil filling time is = 1 Min =60 sec1 Litter oil filling time is = 60/5 = 12 Sec

7.9 Litter oil filling time is = 7.9x12 Sec = 94.8 Sec

2.9 Litter oil filling time is = 2.9x12 Sec = 34.8 Sec

Forward speed of cylinder will be

1000 mm opening time = 94.8 secOpening per 1 sec = 1000/94.8 sec = 10.54 mm/Sec

Retract speed of cylinder will be

1000 mm opening time = 34.8 secOpening per 1 sec = 1000/34.8 sec = 28.73 mm/Sec

Post a Comment