What is braking system?m

Braking system is the combination of different mechanical components which interact in such a manner that it resists the motion of a system frequently by the application of friction. Although the braking systems have a similar purpose, they differ in the working principles. Its main components may include braking pedal, piston cylinder, rotating discs or drum and working fluid etc.Lets discuss types of braking systemTypes of braking system and their details

Mechanical braking system

In a mechanical braking system, the magnitude of applied force on the brake lever is transferred from the driver to the brake drum or rotating disc through mechanical linkages. The force transferred presses the pads against the moving surface which retards its motion due to friction.They have found applications in cycles and low-priced bikes. These days mechanical braking systems are seldom used in the automobile industry because of their ineffectiveness.

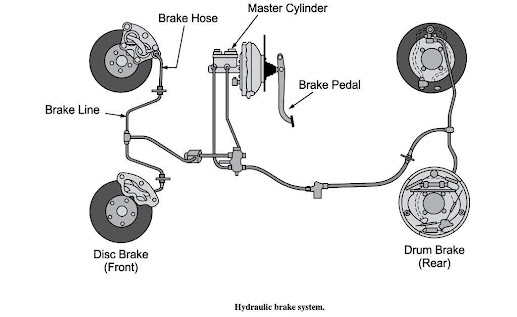

Hydraulic braking system

In a hydraulic braking system, the magnitude of applied force on the brake lever is transferred from the driver to the brake drum or rotating disc through hydraulic pressure of the fluid. As the fluid is in-compressible, the braking force is transferred from the braking pedal to the brake drum or disc usually by piston-cylinder configuration.The use of fluid in hydraulic braking system increases the effectiveness, safety and impact of braking force. Almost all the bikes and normal use cars have a hydraulic braking system.

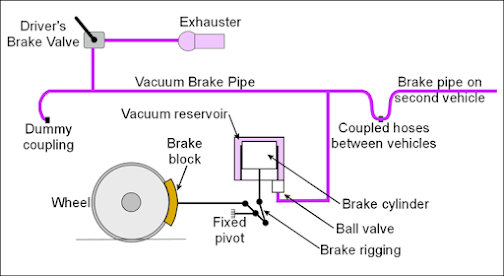

Vacuum braking system

It is also known as servo braking system. In Vacuum braking system the magnitude of applied force on the brake lever transferred from the driver to the brake drum or rotating disc is increased by the incorporation of a vacuum booster. It uses the vacuum produced as a result of suction of air in the gasoline engine or an external pump for diesel engine.

Vacuum braking system assists to decrease the force required to press the brakes. It was used in trains. Now a days, air braking system is used instead because of its effectiveness and less time consumption.

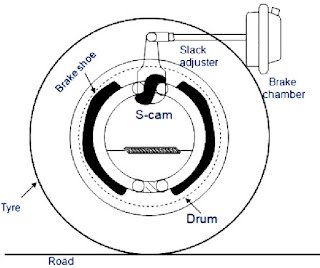

Air or pneumatic braking system

Air or pneumatic braking system uses atmospheric air to achieve braking by transmitting the pedal force of brake to the end rotating disc. End brake force at rotating disc is achieved by using atmospheric air through valves and compressors. Brake force with higher magnitude as compared to hydraulic brake system, is produced by pneumatic brakes and is the basic requirement of the heavy vehicles.

Generally, pneumatic braking system finds its application in heavy vehicles

as hydraulic brakes fail in transmitting large magnitude of brake force up

to long distance. Also, this type of braking system has less chances of

failure due to the presence of a reserve tank of air. Due to these

advantages, high end cars use a pneumatic brake system.

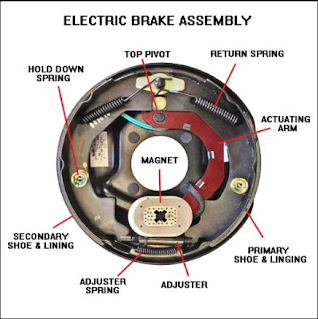

Magnetic braking system

Magnetic braking system achieves braking effect by using magnetic field. This field is produced by using permanent magnets. Basically, its principle lies under the umbrella of generation of eddy current as a permanent magnet is passed through a tube made of copper. This eddy current produces magnetic field which in return gives a braking effect.

Magnetic braking is the modern technology which involves neither friction nor pressure and thus it has negligible wear and tear. In comparison to other braking systems, it has a quick braking response. It finds its application in roller coasters and high-speed trains.

Post a Comment