What is pneumatic system?

Pneumatic system is about the same as hydraulic system. Only the difference is medium that uses in the system like air and fluid. Pneumatic system uses compressed air instead of fluid. Basic pneumatic system

Compressed air is filtered and dried. Filtered and dried compressed

air enhances the pneumatic system performance and increase the

components life.

Pneumatic system design is very simple and reliable.Pneumatic system are most commonly used in automotive industries and manufacturing plant. Usually it is used to drive pneumatic drills, lifting objects and transfer materials.

Pneumatic system design is very simple and reliable.Pneumatic system are most commonly used in automotive industries and manufacturing plant. Usually it is used to drive pneumatic drills, lifting objects and transfer materials.

Components of pneumatic system

Transmission system

A couple of piping systems that transport compressed air to the Linear and rotary actuators.

Air compressor

Air compressor compresses the air and reduces the volume and helps to keep it in a storage tank and finally it supplies the air to the pneumatic system. Air does not come back to the tank, after completing the working cycle air releases to the atmosphere.Pressure gauge

Pressure gauge is also known as vacuum gauge and pressure meter. Pressure gauge determines the pneumatic system pressure and indicates the current pressure level. Two types of pressure gauge are most commonly used in the pneumatic system.- Analog pneumatic pressure gauge.

-

Digital pneumatic pressure gauge.

Exhaust silencer

Exhaust silencer is also known as pneumatic silencer and pneumatic muffler. Usually it is used to vent compressed air to the atmosphere. Generally it is installed to the exhaust port of the solenoid valve.Exhaust silencer reduced the noise during the pressurized air out into the atmosphere. It is also helpful to protect the technicians from contaminants and helps valve from entering dust from the environment.Pneumatic fittings

Pneumatic fittings are used to connect a couple of pipes and tube of the pneumatic system. Pneumatic fittings are designed for lower pressure application and usually offered for various connector sizes and types. As an example: Adapter, Elbow,union, cross, valve and reducer.Solenoid valves

Solenoid valves that are made with the spool assembly inside a casing which operate electrically,change the direction of pressurized air to the actuators. There are several types of solenoid valve used based on their application of uses.Pneumatic pressure sensor

Pneumatic pressure sensor converts air pressure to electrical signal that regulates the functions. Switching output is configured to maintain pressure range and threshold value. Each output PNP and NPN can be set optionally.Air regulator and filter

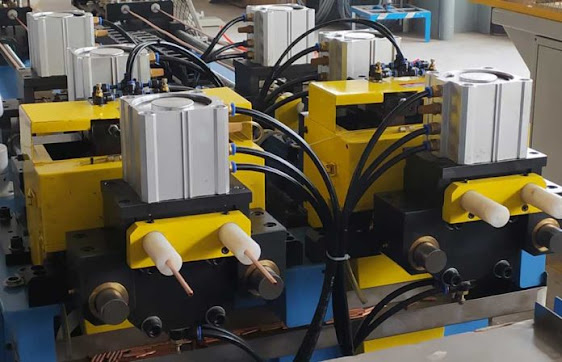

Regulator is used to control the pneumatic system pressure or force. Usually it converts upstream pressure to downstream pressure for the pneumatic system regarding system requirements. Air regulators always supply the constant pressure for the system.Actuators

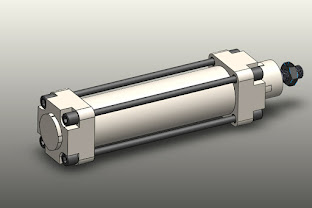

An actuator is a device that converts energy to linear motion or rotary motion that is operated electrically, manually and by air or fluids.Advantages of pneumatic system

1. Pneumatic system is not oily type than compared with hydraulic

system.

2. Pneumatic system is low cost and ease of installation.

3. Not needed pressure reducing valve, relief valve to operate pneumatic system.

4. Product availability.

5. Easy to operate.

2. Pneumatic system is low cost and ease of installation.

3. Not needed pressure reducing valve, relief valve to operate pneumatic system.

4. Product availability.

5. Easy to operate.

Disadvantages of pneumatic system

1. Prone to leakage

2. Can't retain constant pressure at all time

3. Pneumatic system creates unwanted noised due to air exhaust to open environment

4. Can't lift heavy weight compared with hydraulic system.

5. Can't control actuator constant speed.

6. Less life time

7. Pipping system damaged in hot weather condition.

8. System failure is more than hydraulic system.

2. Can't retain constant pressure at all time

3. Pneumatic system creates unwanted noised due to air exhaust to open environment

4. Can't lift heavy weight compared with hydraulic system.

5. Can't control actuator constant speed.

6. Less life time

7. Pipping system damaged in hot weather condition.

8. System failure is more than hydraulic system.

Hello there, I discovered your blog by the use of Google at the same time as searching for a similar subject, your web site came up, it seems good. I've bookmarked it in my google bookmarks.

ReplyDeletePost a Comment