Hydraulic directional control valve

Hydraulic directional control valve is used to control actuators and also their directions. There are several types of directional valve (DCV valve) in hydraulic system according to their applications and construction.Directional control valve is also known as spool control valve. Basic hydraulic pneumatic system components Types of hydraulic pump Hydraulic cylinder speed calculator Hydraulic directional control valve types Basic pneumatic systemDirectional control valve can be classified by their coil type, Single coil and double coil. In a single coil directional valve, one coil is used in the valve and when it is actuated and De-actuated by electrical pulse signal in a moment the actuators complete a full cycle. As an example, when single coil valve is actuated and de-actuated in a moment the actuator moves backward and go forward and clamp the job. Basic hydraulic pneumatic components directional control valve types pump cylinder speed calculator

There are two coils in double coil directional valve. When right side coil is actuated, cylinder moves forward until the coil is de-actuated. When left side coil is actuated cylinder go backward. Usually three types of coils are used in hydraulic system, DC-24volt, AC-110 volt and AC-220 volt.

Single coil Directional control valve working diagram

Directional control valve components

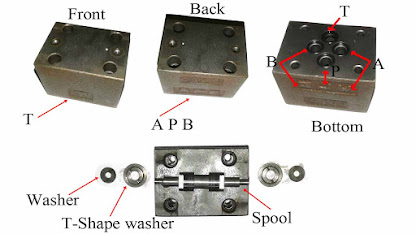

Hydraulic Directional control valve consist of Coil, coil nut, Tube, Spool, Spring, key, Washer, Electrical connection box and block. A YUKEN directional valve components/body parts is shown in the picture below:-Coil nut

Coil nuts are made with plastic. Coils are hold by the plastic nut. Its normally open if the nut turns into counter clockwise direction.Coil

Electrical power are connected to the coils and it creates magnetic field thus spools are pulled by the magnetic field. And if the coil is De-energized, no magnetic field is created and the spool return to the default position.Tube

Two pieces tube are connected horizontally both side of port block. Tube consists of a small spring, key and O-ring. Spring that forces the spool with the help of the key in center position if coil is de-energized. O-rings prevents the leakages of the oil.Block

Blocks are manufactured by casting and after casting it is machining with high precision machines. Spool assembly are stay inside the block. Spool are guided by two T shape washers in both side of the block. And other two pieces flat washer forces the T shape washer to moves spool forward and backward.There are several ports are located bottom of the block and it is marked by A,B,P,T sign.A and B = Cylinder connecting port

P = pressure port

T = Tank port

Post a Comment